Sialex®focus on fluids

Our

Mission

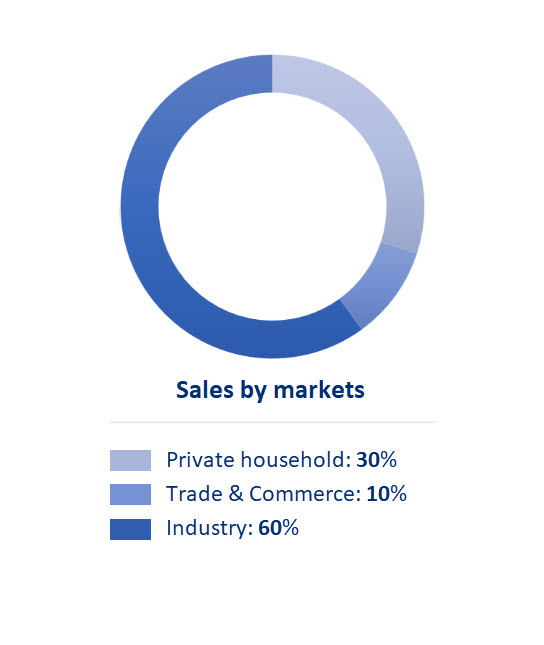

We at Phoenix Ring Manufaktur have made it our mission to provide private households, commerce, trade, but also industry with an environmentally friendly and cost-effective water treatment system for the treatment of limescale and rust.

The special thing about Sialex® is that with every installation, the use of chemicals is reduced a bit, ideally even completely replaced.

At the same time, it is an essential concern of ours to maintain a fair and open relationship with our prospects and customers, as well as with our partners, suppliers, competitors and also our employees.

An important part of our success lies in an honest and individually customized testing opportunities. For example, our potential and new customers are supported directly on site, if possible, and realistic expectations are always worked out together with them.

A healthy and sustainable growth of our company is, as a result, year after year the result.

Management

& Team

Over the past decade, Phoenix Ring Manufaktur has become an important contact for thousands of private users and also for the industry.

The product Sialex®Ring is now not only a household name in many parts of the world, but has also become indispensable in other sectors of the economy, like in the field of physical water treatment.

The company is managed by Sven Gagel (49), who has been coordinating an international team of chemical engineers, proven water experts, but above all incredibly great people for almost 20 years. Since 2006, Gagel’s team has placed great emphasis on customer service at the highest level.

This is also evidenced by the fact that in 2014 a dedicated service company (Sialex®Service Internacional) was founded in South America with headquarters in Mexico, which is exclusively responsible for the smooth service process in Latin America and the Caribbean.

Together with the main responsible exclusive coordinator, Eberhard Wolff (62), and his team of highly trained engineers and technicians, new applications and exciting tasks have been solved together worldwide since then, as well as ensuring fast pre- and after-sales support that is optimally adjusted to the customer.

The most important steps in the Sialex®Ring manufacturing process (e.g. quality control, product design and development), as well as marketing and sales, are carried out exclusively by the company’s own employees.

Facts

& Figures

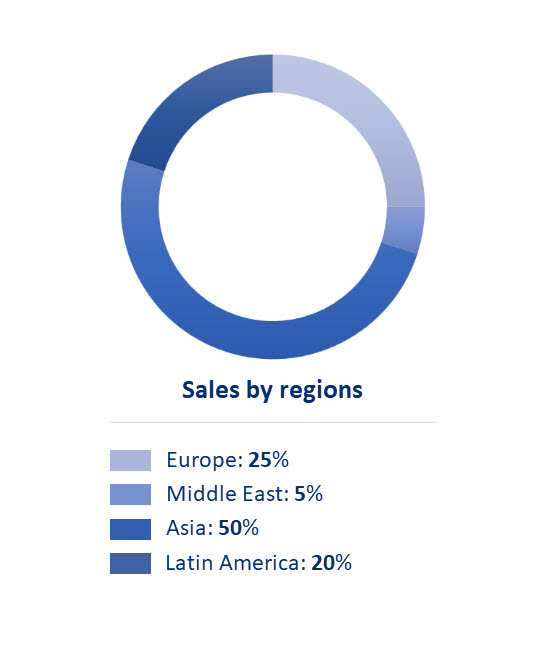

Sialex® products for the treatment of limescale and rust are used in private households (e.g. washing machines, dishwashers, coffee machines, showers, surfaces, fittings, etc.), but also in the industrial sector (heat exchangers, district heating, air conditioning systems, cooling towers, etc.).

Sialex® products are also successfully used in agriculture and in the manufacturing process of oil extraction.

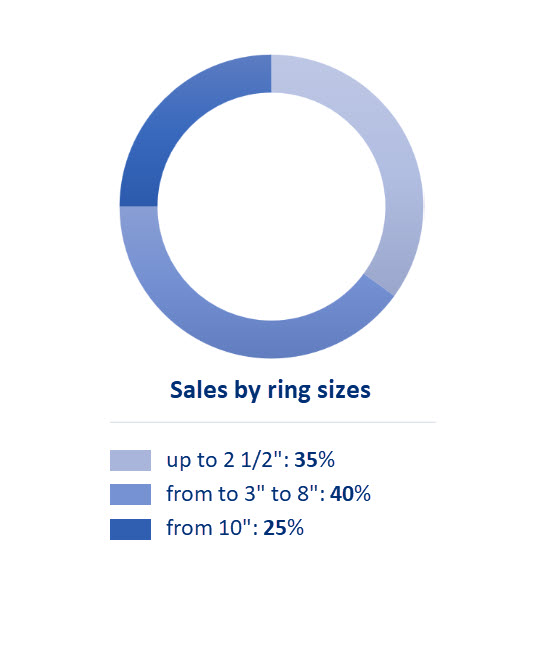

Sialex® products Made in Germany are sold in Germany by the company’s own customer consultants and national sales partners. Internationally, Phoenix Ring Manufaktur works with sales partners, OEM’s and intermediaries who know individual industries and specific sub-sectors very well. Sialex®Rings are available from DN15 (1/2″) to DN1200 (48″). Other sizes, special configurations and custom designs are available upon request.

Social

Engagement

Doing business these days usually means making a profit. For us and as a responsible member of our society, however, this also means getting involved in the region or supporting where help is actually needed and giving something back.

We at Phoenix Ring Manufaktur do this on the one hand through intensive cooperation with local institutions, and on the other hand through concrete financial support. An example of this is our cooperation with our socially very committed partner Eberhard Wolff. In the meantime, we have been able to provide needy families in Mexico with clothing, toys and basic foodstuffs on several occasions. Furthermore, we have been supporting the association for children with cancer in Darmstadt and here in the Odenwald, but also the local hospice, for years and at regular intervals and the social organization “Aktion Mensch”, which is known far beyond the borders, for years and at regular intervals.

If you, your association or your social group are interested in a sponsorship by the Phoenix Ring Manufaktur, please do not hesitate to contact us at verantwortung@phoenixringmanufaktur.de and outline your request briefly. We will then be happy to check your request for feasibility

We live

sustainability

Sialex®Ring – The environmentally friendly solution for water treatment, against limescale and rust

Sialex®Ring, a physical water and system optimizer that removes limescale, rust and other deposits in water-bearing pipes and equipment, contributes to sustainability in many ways, not only in private households but also in industry.

Sialex®Ring technology avoids the annual use of many tons of aggressive chemicals that are released into the environment via wastewater from, for example, traditional chemical water treatment plants.

The permanent removal of limescale by Sialex® optimizes the efficiency of water-bearing equipment and machinery (e.g. cooling circuits) and significantly reduces energy requirements and as a result, CO2 emissions.

Sialex®Ring – Water treatment without chemicals

Sialex®Ring preserves the naturalness and purity of the globally limited water resource. Without the use of critical raw materials, without consumables (e.g. regenerating salt) and without electricity, Sialex®Ring dissolves existing lime deposits, removes rust and also biofilm tens of thousands of times in many countries around the world.

The use of regeneration salts used by the traditional chemical water softeners against limescale and the use of biocides against biofilm are a thing of the past. With the use of Sialex®Ring an active contribution is made to preserve the natural basis of life and to use it sustainably.

Sialex®Ring – Reduction of CO2 Emissions

Info: Already a 1 mm thick lime layer increases the energy demand by approx. 10% in industrial water heating equipment like boilers, which is traduce to a reduction of CO2 emissions of approximate 3-10%, through energy savings and thus actively contributes to counteracting global warming.

The generation of a single kilowatt hour of electricity in Germany emits an average of 474 grams of CO2 as direct emissions (German electricity mix with 40% green electricity).

With every ton of limescale that industrial customers remove from their systems, but also with every single private hot water boiler, every boiler that is more effective and energy-saving when free of limescale, the Sialex®Ring reduces CO2 emissions through energy savings and thus actively contributes to counteracting global warming.